WHAT IS A COIL-WOUND HEAT EXCHANGER

The coil-wound heat exchanger is a sophisticated high-tech equipment designed for gas liquefaction and processing units

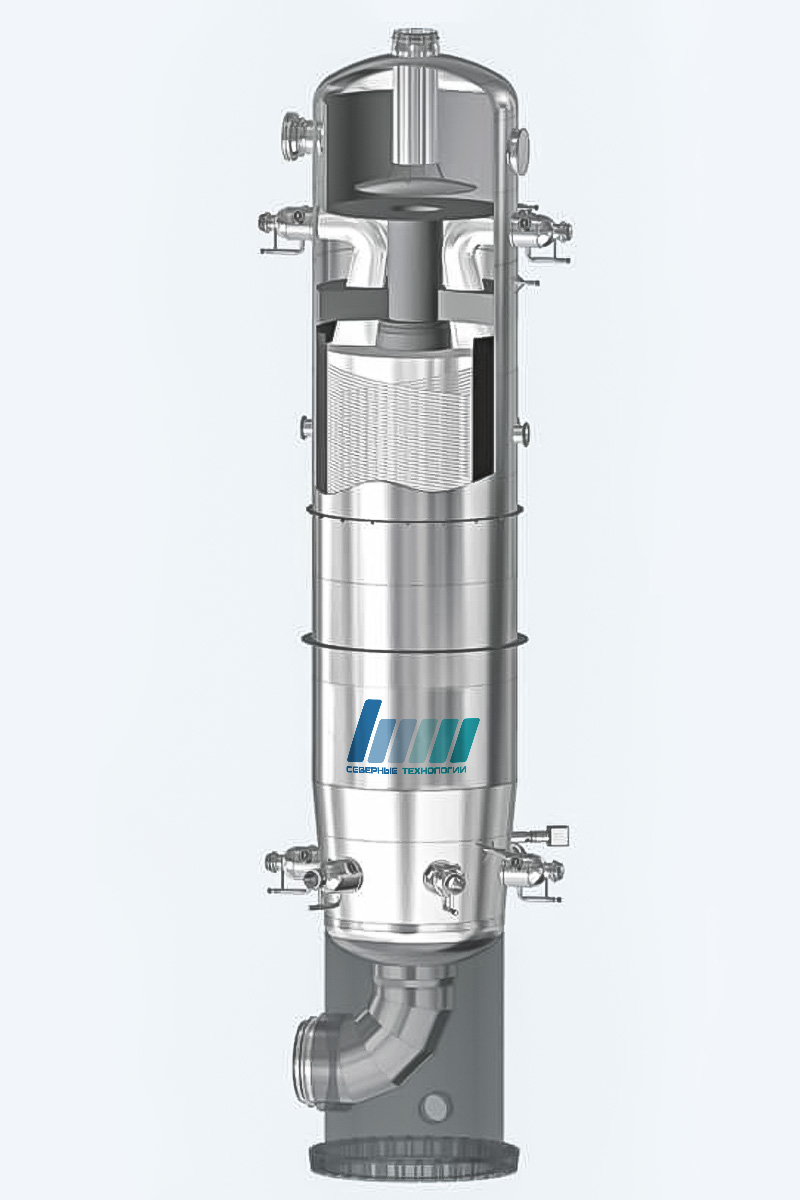

Within this type of heat exchanger, several layers of tubes are helically wound around a large center tube, known as a mandrel. This tube bundle can be designed in such a way that it can contain more than one tube fraction to accommodate different process media. Both ends of the tubes are welded to tube sheets or ring pipes. A ready tube bundle is placed into the shell.

Due to the special “spring-like” design, CWHEs are extremely robust. Supporting a temperature range between –269°C and +650°C, they can handle significant temperature and pressure differences. The tube bundle simply shrinks or expands during start-up or shut-down, for instance, to accommodate these large changes in temperature. The support system prevents the tube bundle from sagging.

The robust design and wide temperature and pressure make CWHE ideal for a broad spectrum of cryogenic and high-temperature applications, especially where fast temperature changes and cyclical temperature and pressure loads are specified.

CWHEs are used mainly for clean fluids where mechanical cleaning is not required in the following plants and applications:

- LNG and natural gas processing plants;

- Acid removal;

- Solar thermal power plants;

- Methanol synthesis

- Сonversion of carbon monoxide to carbon dioxide;

- Hydrogenation;

- Methanation;

- Vaporisation with water bath

APPLICATIONS

The offered heat exchanging systems can provide solutions for a wide range of applications.

The robust design and wide temperature and pressure make CWHE ideal for a broad spectrum of cryogenic and high-temperature applications, especially where fast temperature changes and cyclical temperature and pressure loads are specified.

CWHEs for LNG plants

These CWHEs act as the main cryogenic heat exchanger (MCHE) or precooler in numerous LNG plants worldwide. CWHEs are used in different liquefaction processes with a wide load spectrum.

Benefits:

- High efficiency due to flow channel optimization with computational fluid dynamics.

- High reliability and robustness.

- Sophisticated liquid distributor to cope with wide load ranges.

- Adjustable tube side and distributor control to optimize heat transfer at different operation points in order to maximize efficiency or LNG output.

CWHEs as isothermal reactors

The isothermal reactors are fixed-bed reactors suitable for endothermic and exothermic catalyst reactions with indirect heat transfer. The main difference between these and other reactors with integrated heat exchangers is that the helically coiled tubes are immersed in the catalyst bed. They are characterized by a significantly higher heat transfer compared with tubular reactors with a catalyst inside the tubes, which results in a much smaller heating area. For example, the tube bundle surface area of reactor is approximately 25%–45% smaller than that of a tubular reactor with the same performance for methanol synthesis processes.

The isothermal reactors can be used for gas/ gas, gas/liquid and liquid/liquid reactions, making them an excellent solution for various processes in the chemical industry. These include:

- methanol synthesis

- shift conversions

- claus processes

- hydrogenation

- methanation

Benefits:

- Highest catalyst volume per reactor volume for an isothermal reactor

- Cost advantages through compact design

- Easy temperature control by adjusting the steam pressure

- Integrated steam drum with natural boiler water circulation

- Smooth behaviour during catalyst activation, normal operation, fast start-up and shut-down procedures and catalyst deactivation

CWHEs as water bath vaporisers

The water bath vaporisers (WBVs) are a robust and reliable solution for the gasification of cryogenic fluids within a very large capacity range. A WBV unit consists of a water-filled vessel with a submerged coiled tube bundle. The water can be pumped (for a fast, responsive design) or flow in natural circulation (for a simple, cost-effective design). The liquefied gas that passes through the tubes is instantly heated by the water

and thus vaporised up to product temperature and pressure.

WBVs are primarily installed in back-up systems at air separation plants that must be started in a matter of seconds/minutes to ensure continuous plant operations. However, they are also used in petrochemical and LNG plants, for instance to heat flare gas or boil-off gas.

Benefits:

- Vaporisation of up to three product streams in one single heat exchanger.

- Pressure build-up of cryogenic tanks can be incorporated in the same heat exchanger.

- Increased safety due to water bath thermal buffer in the event of interruption to steam supply.

- Optional usage of special tube inserts to reduce pressure and flow fluctuations and therefore improve operational stability and process safety.

- Suitable solution to handle ice formation during normal operation due to flexible ring distributor.

- Small footprint due to high energy density and vertical design.