NORTHERN

TECHNOLOGIES

Northern Technologies Limited Liability Company

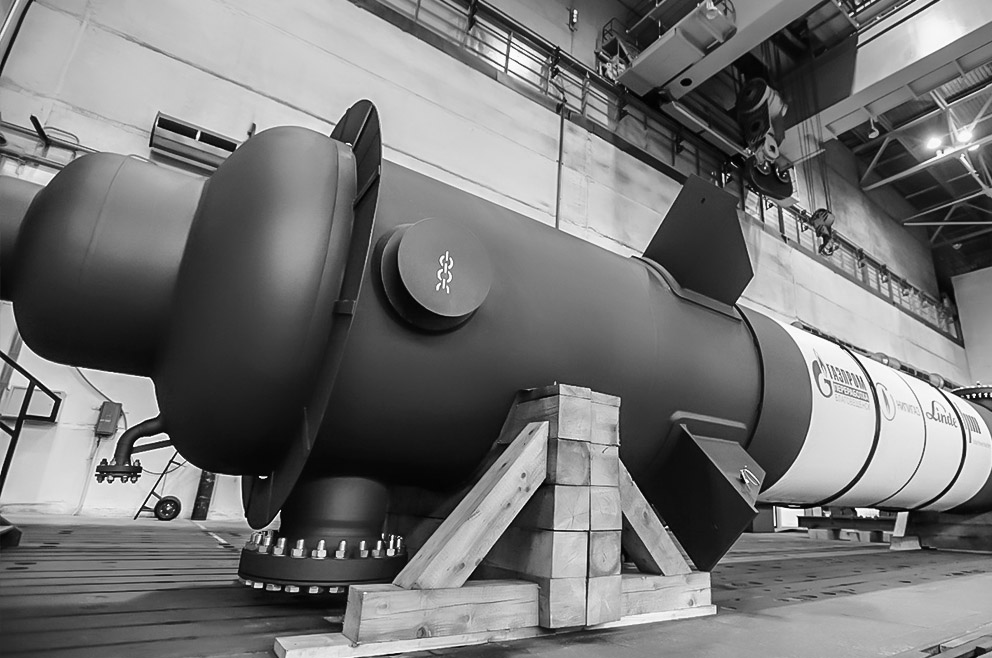

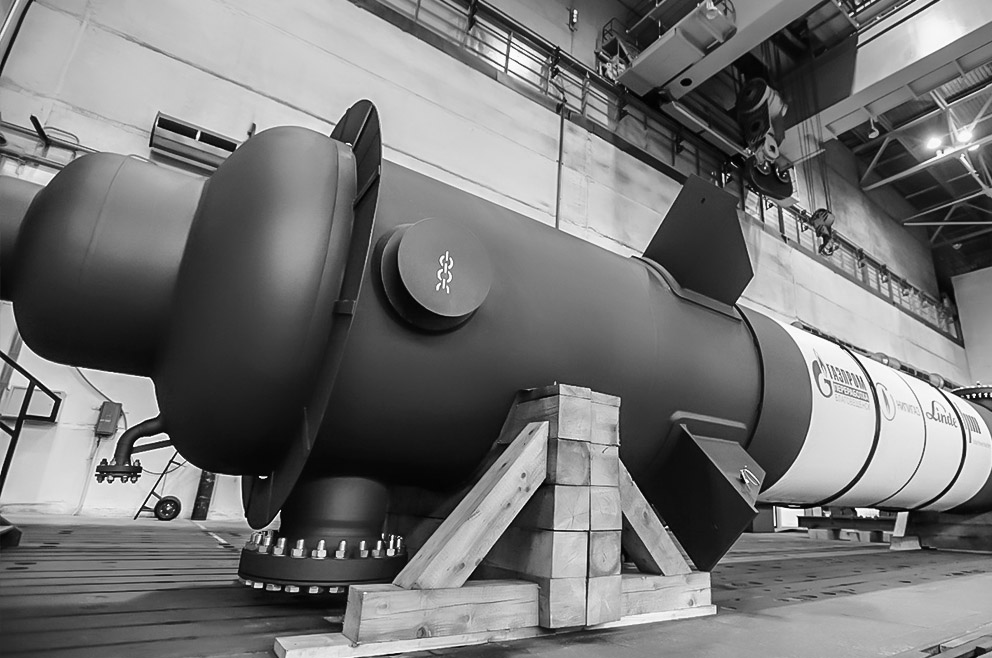

A joint venture that has localized in Russia the manufacturing of coil-wound heat exchangers (CWHE), key equipment in natural gas liquefaction and processing plants. Manufacturing was launched in 2017.

Northern Technologies start-up project was an order for manufacturing of three hydrogen reactor preheaters for the Amursky Gas Processing Plant. All three heat exchangers are intended for use in the helium production process, which has now begun.

In 2021 the company exported to the EU five heat exchangers successfully installed in a petrochemical plant in Spain, manufactured two water-bath vaporisers for gas separation plants and completed a liquefier tube bundle for a liquefied natural gas (LNG) plant

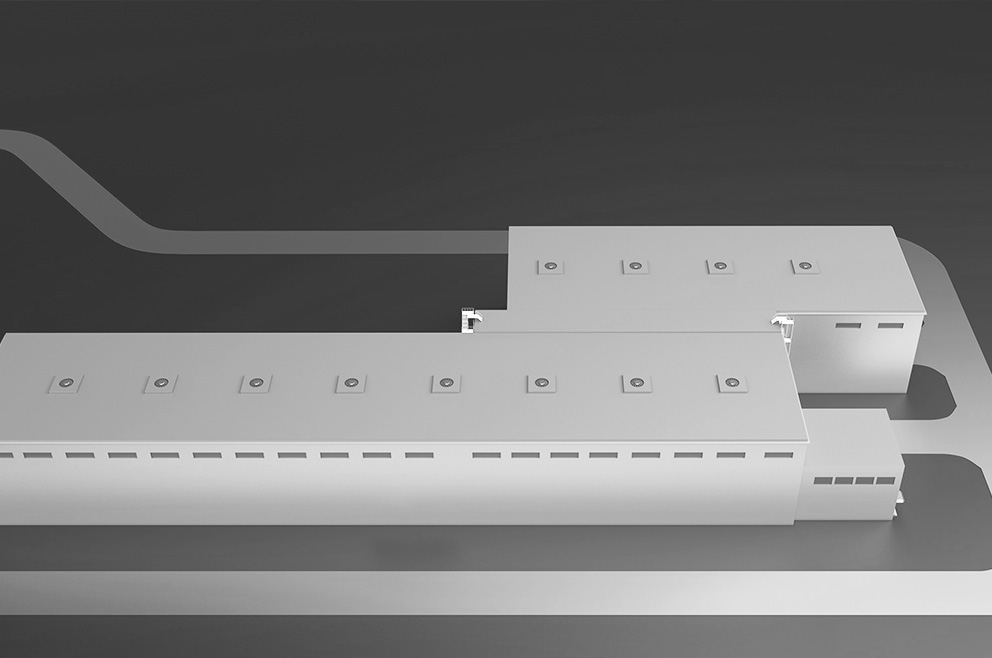

The company’s workshop, located in close proximity to the cargo berths of the Grand Port of St Petersburg, allows for annual shipments of large-sized equipment by water from May to November.

Northern Technologies has experience in manufacturing equipment in accordance with Russian and international standards: GOST, EN, ASME. The products are certified in accordance with the requirements of the EAU. The company has had its quality management system (QMS) and products certified in the Intergazsert Voluntary Certification System. Regardless of design standards and certification obligations, the company’s products always meet high internal quality requirements as well as customer requirements for operational safety with the highest possible performance.

A joint venture that has localized in Russia the manufacturing of coil-wound heat exchangers (CWHE), key equipment in natural gas liquefaction and processing plants. Manufacturing was launched in 2017.

Northern Technologies start-up project was an order for manufacturing of three hydrogen reactor preheaters for the Amursky Gas Processing Plant. All three heat exchangers are intended for use in the helium production process, which has now begun.

In 2021 the company exported to the EU five heat exchangers successfully installed in a petrochemical plant in Spain, manufactured two water-bath vaporisers for gas separation plants and completed a liquefier tube bundle for a liquefied natural gas (LNG) plant

The company’s workshop, located in close proximity to the cargo berths of the Grand Port of St Petersburg, allows for annual shipments of large-sized equipment by water from May to November.

Northern Technologies has experience in manufacturing equipment in accordance with Russian and international standards: GOST, EN, ASME. The products are certified in accordance with the requirements of the EAU. The company has had its quality management system (QMS) and products certified in the Intergazsert Voluntary Certification System. Regardless of design standards and certification obligations, the company’s products always meet high internal quality requirements as well as customer requirements for operational safety with the highest possible performance.

COMPANY’S

MANAGEMENT

«The company’s strategic goal is to ensure technological sovereignty in terms of production of coil-wound heat exchangers for all Russian LNG projects»

P.V. Krylov

GENERAL DIRECTOR

Northern Technologies Limited Liability Company

Pavel V. Krylov

COMPANY’S

HISTORY

Since our launch, we have evolved from a CWHE manufacturer to the provider of comprehensive services, including engineering, manufacturing, onsite maintenance as well as warranty and in-service monitoring.

2017

Manufacturing set-up

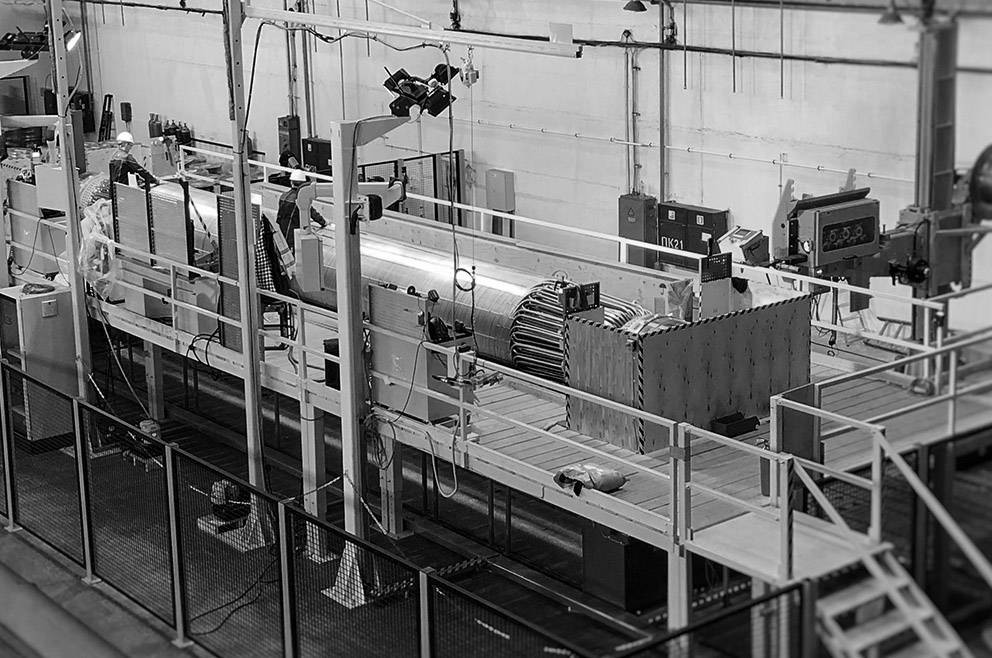

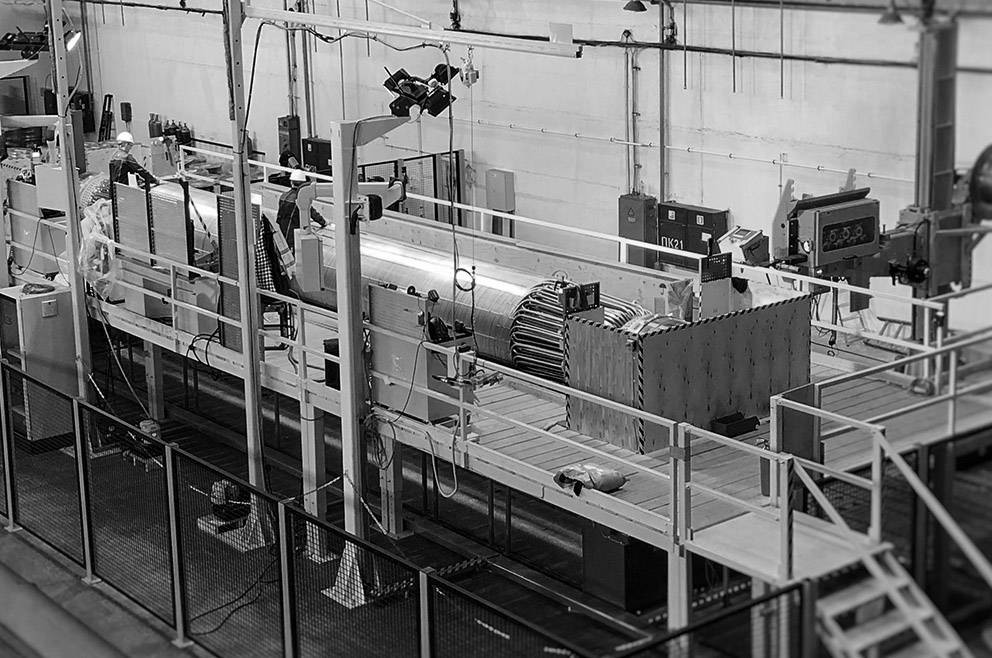

Set-up of workshop in St. Petersburg

In May 2017, a ceremony was held in St. Petersburg to launch the production of coil-wound heat-exchanging equipment applied in medium- and large-scale liquefaction and natural gas processing plants. Work on the first heat exchanger began at the company’s workshop in November 2017.

2018

Manufacturing of the first CWHE

Shipment of the first hydrogen reactor preheater for the Amurskii GPP

In July 2018, the first coil-wound heat exchanger was manufactured for the Amur Gas Processing Plant. The quality standards have been confirmed by obtaining TR TC and ISO-9001 certification.

2019

New workshop

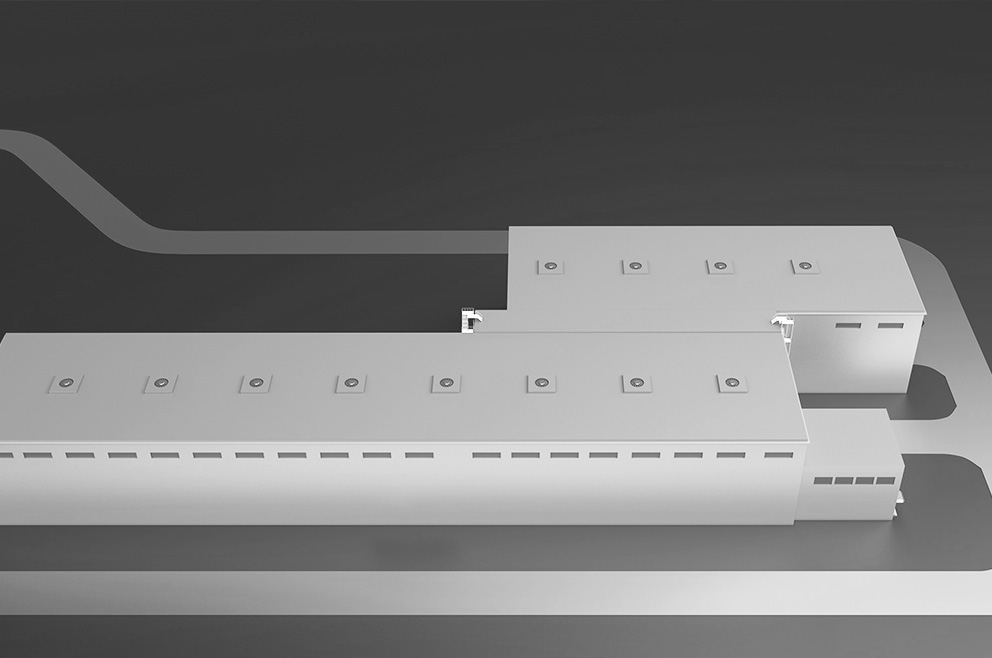

Acquisition of a 6,000 sq m production site at the Bolshoy Port of St Petersburg

- EN ISO 3834-2 certification

- EN 13445-4 certification

- AD 2000-Merkblatt HPO certification

2020-21

Increase in production volumes

Expansion of product range

Between 2017 and 2021, the company has manufactured 11 CWHEs. These included the first CWHE bundle produced in Russia for a large-capacity LNG plant. 5 CWHEs were exported to EU.

2022

Reorganisation of Company

Change of major shareholders

- Strategic partnership with GL Engineering LLC.

- Signing of a contract for supply of equipment for the natural gas processing and liquefaction complex at Ust-Luga.

2017

In May 2017, a ceremony was held in St. Petersburg to launch the production of coil-wound heat-exchanging equipment applied in medium- and large-scale liquefaction and natural gas processing plants. Work on the first heat exchanger began at the company’s workshop in November 2017.

2018

In July 2018, the first coil-wound heat exchanger was manufactured for the Amur Gas Processing Plant. The quality standards have been confirmed by obtaining TR TC and ISO-9001 certification.

2019

- Acquisition of a 6,000 sq m production site at the Bolshoy Port of St Petersburg

- EN ISO 3834-2 certification

- EN 13445-4 certification

- AD 2000-Merkblatt HPO certification

2020-2021

Between 2017 and 2021, the company has manufactured 11 CWHEs. These included the first CWHE bundle produced in Russia for a large-capacity LNG plant. 5 CWHEs were exported to EU.

2022

- Reorganisation of Company

- Strategic partnership with GL Engineering LLC.

- Signing of a contract for supply of equipment for the natural gas processing and liquefaction complex at Ust-Luga.

NORTHERN TECHNOLOGIES TODAY

Cooperation of highly qualified specialists from Northern Technologies and GL Engineering with leading industry suppliers to provide customers with unique products and services localized in the Russian market